Instrumentation in a pandemic: How the Department of Chemistry Instrumentation Facility rapidly adapted to Covid-19

Rotating reservation systems and strict social distancing helped the DCIF experience as little interruption as possible.

Under regular circumstances, the Department of Chemistry’s Instrumentation Facility (DCIF), is a 24/7 operation that services nearly 100 individual research labs from not only the MIT community, but external universities and corporations alike, at a rate of approximately 300 users a month. In 2018, the DCIF benefitted immensely from the generous support of alumni and friends who contributed to a fundraising drive to replace and renew outdated equipment in the facility.

When the Covid-19 pandemic forced all on-campus activity to come to a screeching halt last March, the stewards and staff of the DCIF were faced with the challenge of quickly adapting their policies and procedures to accommodate the newly instituted guidelines for safely working at a social distance, all while preventing contamination.

Addressing contamination potential

Walt Massefski, the DCIF director, worked with his staff — Operations Manager John Grimes, Research Scientist Mohan Kumar, and Research Specialist Bruce Adams — to implement the necessary changes to day-to-day activities in the subbasement of the Dreyfus Building. First, the group took into consideration the two types of contamination they were facing: airborne contamination, the result of virus that is exhaled by an infected individual traveling through the air to another individual, and is minimized by proper use of masks and social distancing; and touch contamination, the result of an infected individual either breathing on or touching a surface (door handle, keyboard, and the like) and another individual touching that surface and subsequently touching their eyes, nose, or mouth.

“We developed our plan to limit airborne contamination by strict adherence to MIT’s mask and social distancing guidelines: Masks must be worn by all individuals in the lab at all times, and all individuals must stay six feet from each other (if two people can extend their arms and touch fingertips, they are too close),” says Massefski. “We also designed our lab-use plan to meet the time and space guidelines instituted by the vice president for research: no more than one person in every 160 square feet of lab space, and no more than 10 minutes in that space at one time.”

The considerable size of the DCIF — and the need for the seven nuclear magnetic resonance (NMR) instruments it houses to social distance, even when there isn’t a pandemic — made the distance guidelines relatively easy to meet in the NMR space. The facility’s mass spectrometry space, on the other hand, was another story.

“During Phase 1, we significantly restricted the use of the mass spectrometry part of the lab,” explains Massefski. “During Phase 2, we have adopted a rotating reservation system for the instruments that are close to each other.”

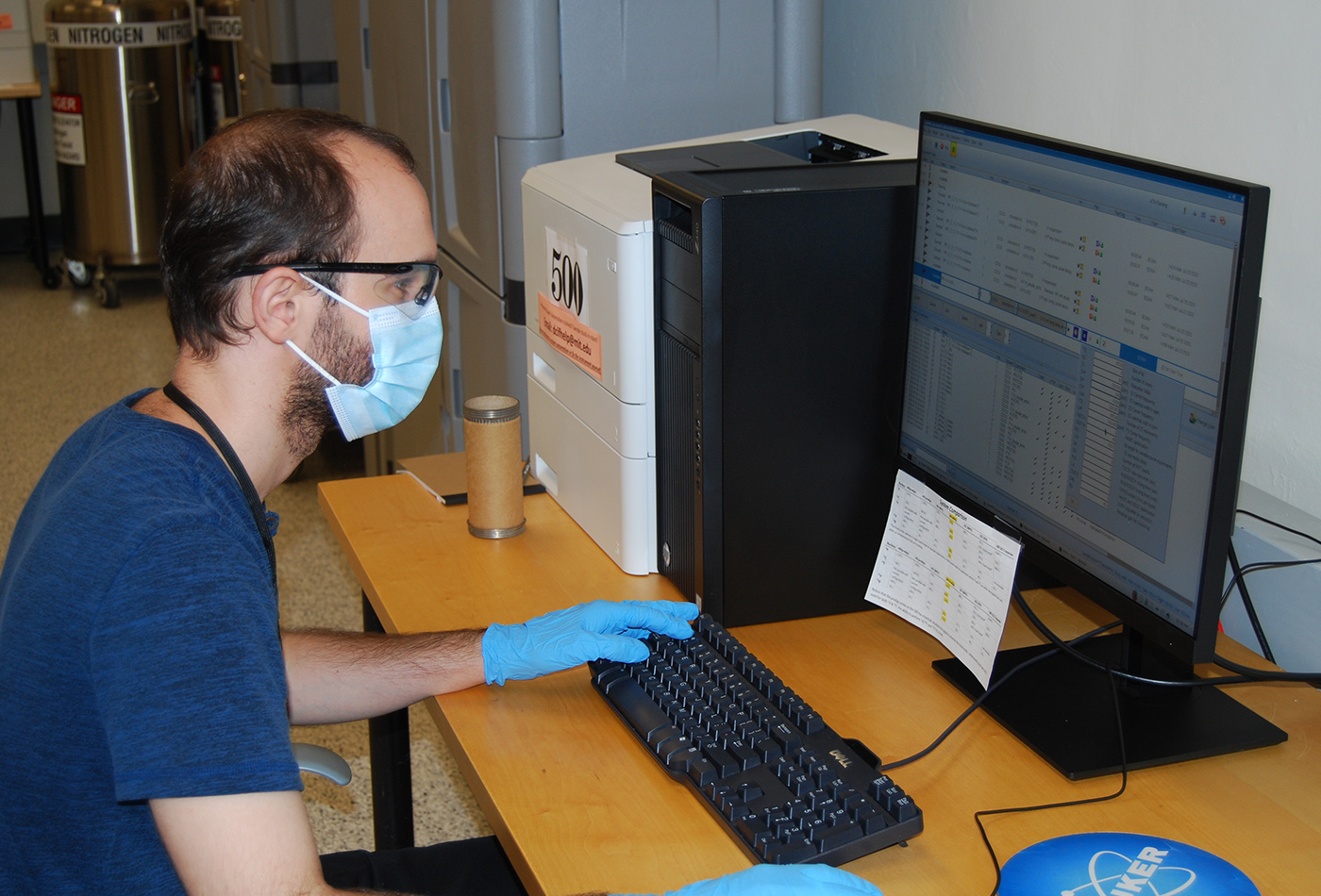

“We developed our plan to limit touch contamination based on a double-barrier model that I learned while working at an MIT-affiliated molecular diagnostics startup earlier in my career; users of the lab must wash their hands when they arrive in the lab, don a fresh pair of gloves, and keep those gloves on while they are in the lab,” says Massefski. “Gloves are discarded as users exit the lab. Since everyone in the lab is wearing gloves (and a mask), accidental touch contamination for any reason by one individual is limited to the surface, and not transferred to the next individual, hence the double-barrier. By washing when you arrive, you limit the possibility that you will carry virus from outside the lab to the inside the lab; by wearing gloves inside the lab, you limit the possibility that you will carry virus from inside the lab to outside the lab, again a double-barrier approach. While we hope that no one enters the lab infectious, these steps, along with regular surface cleaning, are the best approach we can think of to maximize transmission control.”

Implementing these new policies involved extensive communication between the DCIF lab and lab staff and users of the lab. Massefski and his team sent out a number of detailed email notifications, and developed signage to remind everyone of the important steps to take for transmission control. To their credit, the facility’s users were happy to follow the new processes. Users have been respectful of the importance of ensuring a safe work environment for all, and receptive of reminders to wash hands and wear gloves in the instance of a user forgetting the newly instated policies.

“The difficulty has been for me to keep in mind some of the policies in my daily workflow,” says John Grimes, the DCIF’s operations manager. “A large amount of my time is spent interacting with students, be it to answer their questions or train them to use our instruments. When I am trying to show them how software works, or how to load their samples in a robot, doing so from a two-meter distance can be challenging. It is easy for both of us to end up closer than that. I must constantly remind myself and them that we can’t both lean in at the same time to see what it is I am talking about.”

Adjusting to the new normal

Throughout this ordeal, the DCIF staff’s priority has been to continue to train young scientists and make key resources available to them in the social distancing and restricted-access environment. The group relied on their honed skills of both applying software automation to instrument access and managing a complex, computer-driven lab.

“As a shared facility, we used to get more users, interesting discussions, and it was always a really busy place,” says research scientist Mohan Kumar. “The new guidelines can make it feel like we are not doing science and not working in the lab. “

However, despite how things may feel, the lack of population in the lab itself has no bearing on its scientific productivity. All of the facility’s systems are networked, so from the inception of the lab, the systems were built in such a way that that chemists could access their NMR and MS data as easily from home as they could from their lab.

Because of this, when the pandemic hit, the DCIF was mostly ready to meet data-access needs. At the start of Phase 1, they rapidly designed and implemented remote automation tools so that someone could drop samples at the door of the lab, or the building, or at a remote location, and a DCIF staff member could efficiently add those samples to running NMR queues. They developed processes in which users of the DCIF high-resolution mass spectrometers could spend a few minutes in the lab adding samples to the instrument platform, then work remotely to acquire essential data from these samples, limiting the amount of time they actually spent in the lab.

Now that the campus has entered Phase 2, the DCIF staff and stewards have extended their ability to effectively conduct new-user trainings using a combination of video and slide presentations, as well as providing instrument access over a Virtual Network Computing or remote desktop connection and a Zoom link. Massefski credits the facility’s trial-by-fire implementation of Phase 1 protocols as being instrumental in helping his staff smoothly transition into the Phase 2 regulations. Mirroring the Institute’s policies, the facility had to learn to walk in a Covid-19 society before it could run.

“We gave significant thought to how we would prepare for a research reopening during the shutdown, including conversations with colleagues from labs all over the world to hear their advice about best practices,” says Massefski. “Since the shutdown was fairly extensive, we had plenty of time to consider the advice of others and to think about how the social distancing restrictions might impact lab operations. Once the details of the VPR guidance were available, we were able to put a proposal out to the department and our faculty advisor, chemistry professor Mo Movassaghi. His experience as advisor for the lab has been invaluable, and he was a touchstone for our transition to Phase 2.”

In addition to taking on contamination control training in the lab, staff members took on the task of receiving requests from users to run samples or carry out experiments that they would normally have done themselves. Massefski remarks, “Considering the size of our user base, even at the 25 percent level at which that labs were operating in Phase 1, this became a considerable effort. The DCIF staff contributed an outstanding level of skilled communication and professionalism in handling these requests.” Though the DCIF staff’s work is ongoing, and the effects of the pandemic are far from over, the results of their efforts are both impactful and sincerely appreciated.